.jpg?width=250&height=250&name=Rob%20(003).jpg)

About

I am Rob Frechette, the exclusive MST Representative for North America. I have worked in the dairy industry for over 26 years and with MSTC for much of those. I am happy to represent this novel approach to extending the shelf life of fresh pasteurized milk without any compromise of flavor or nutrition.

My company Phil 413 Consulting is named after two things that mean a lot to me. First, Philippians 4:13 is a Bible verse I try to live my life by, and second Phil Frechette, my father, was a great man who lived his life to represent Christ and to better the food, beverage, and dairy industries.

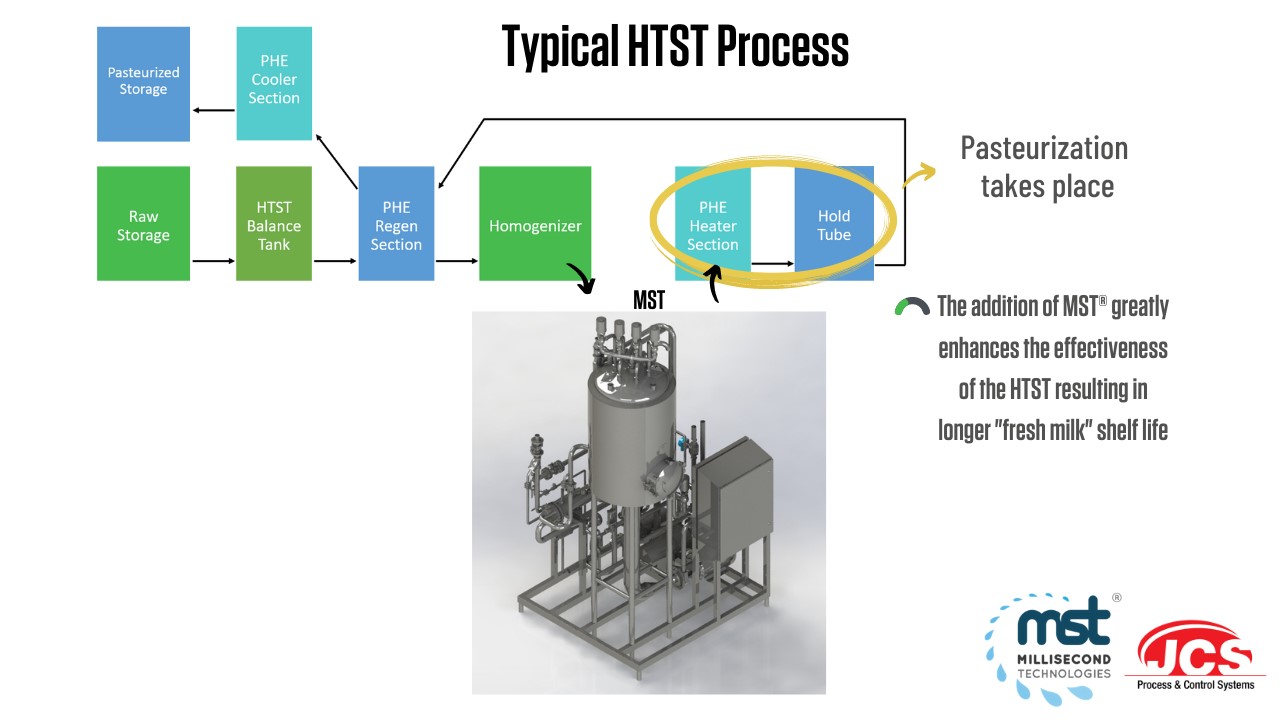

What is MST

MST is a new and innovative technology (Patented by MSTC) to greatly extend the shelf life of liquid products produced at temperatures below that of normal pasteurization, without compromising taste or nutrients. It consists of a jacketed and insulated MST Chamber, the appropriate array of MST microdroplet forming nozzles, hot water set sized appropriately to accomplish the MST effect, vacuum pump, product delivery valve manifold, tank outlet pump, all the required instrumentation, controls, means of connectivity, via Ethernet, to the pasteurizer to which it will be integrated, and HMI (human to machine interface).

The MST System is cleaned in place (CIP) with the HTST, eliminating the need for any external CIP system.

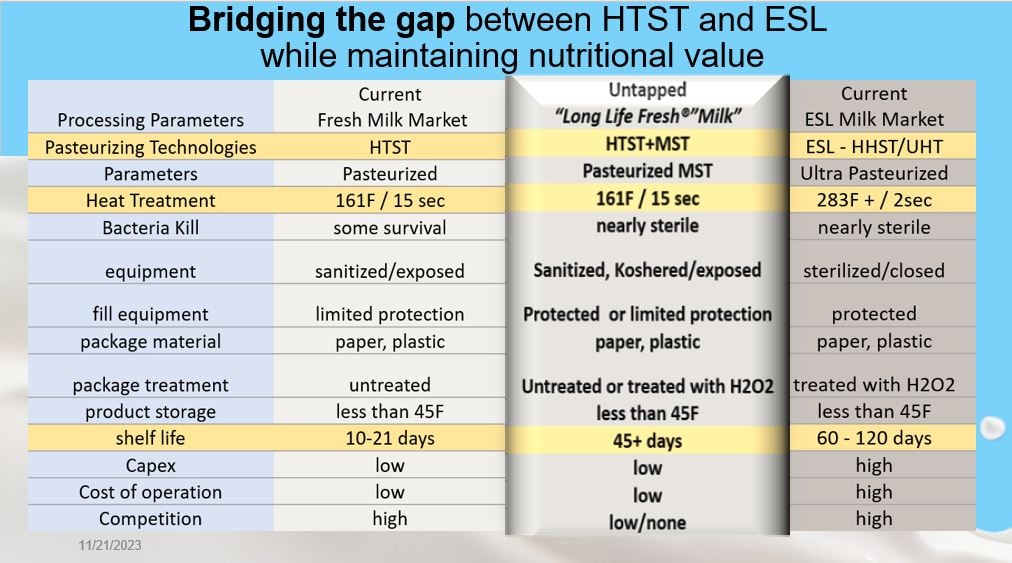

Bridge the Date Code Gap, but maintain the Fresh Quality of the Milk

Company news

MSTC Proposal 103 at NCIMS passes all votes unanimously. FDA concurs and the new upcoming PMO opens the door for MST systems to be installed in the US on Grade A milk processes.

.jpg?width=1200&length=1200&name=How%20MST%20works%20(002).jpg)